Manufacturer of Teak Timber - Film Faced Plywood – ROC

Manufacturer of Teak Timber - Film Faced Plywood – ROC Detail:

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

7.5 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

690 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.68 Min: 0.81 |

Check out |

|

Damage Rate |

% |

85% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

6997 |

Check out |

|

Lateral |

6090 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

59 |

Check out |

|

|

Lateral |

43.77 |

Check out |

||||

|

6 |

Cycle Life |

About 15-25 Repeated Using Times Acoording To Projects By Formwork Application |

||||

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

8 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

605 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.59 Min: 0.79 |

Check out |

|

Damage Rate |

% |

82% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

6030 |

Check out |

|

Lateral |

5450 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

57.33 |

Check out |

|

|

Lateral |

44.79 |

Check out |

||||

|

6 |

Cycle Life |

About 12-20 Repeated Using Times Acoording To Projects By Formwork Application |

||||

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

8.4 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

550 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.40 Min: 0.70 |

Check out |

|

Damage Rate |

% |

74% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

5215 |

Check out |

|

Lateral |

4796 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

53.55 |

Check out |

|

|

Lateral |

43.68 |

Check out |

||||

|

6 |

Cycle Life |

About 9-15 Repeated Using Times Acoording To Projects By Formwork Application |

||||

|

ROCPLEX Film faced plywood Save cost |

||

|

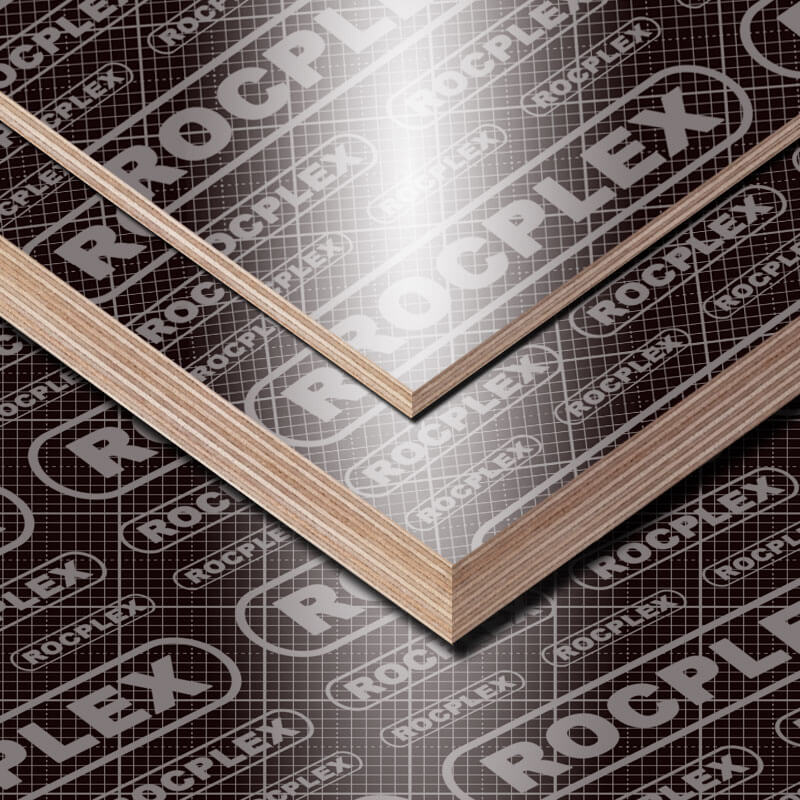

Be special for phenolic glue and film |

The film faced plywood can be disassembled and used repeatedly for both faces,saving 25% of the cost. |

|

|

Optimization for the special grade of core |

||

|

Be special for adhesive |

||

|

ROCPLEX Film faced plywood Shorten duration |

||

|

Excellent effect of demoulding |

Shorten 30% of the duration. |

|

|

Avoid the reconstruction of the wall |

||

|

Be easy to incise and blend |

||

|

ROCPLEX Film faced plywood the high quality of casting |

||

|

The flat and smooth faces |

The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. |

|

|

The structure of waterproof and breathability |

||

|

The edges are polished carefully |

||

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

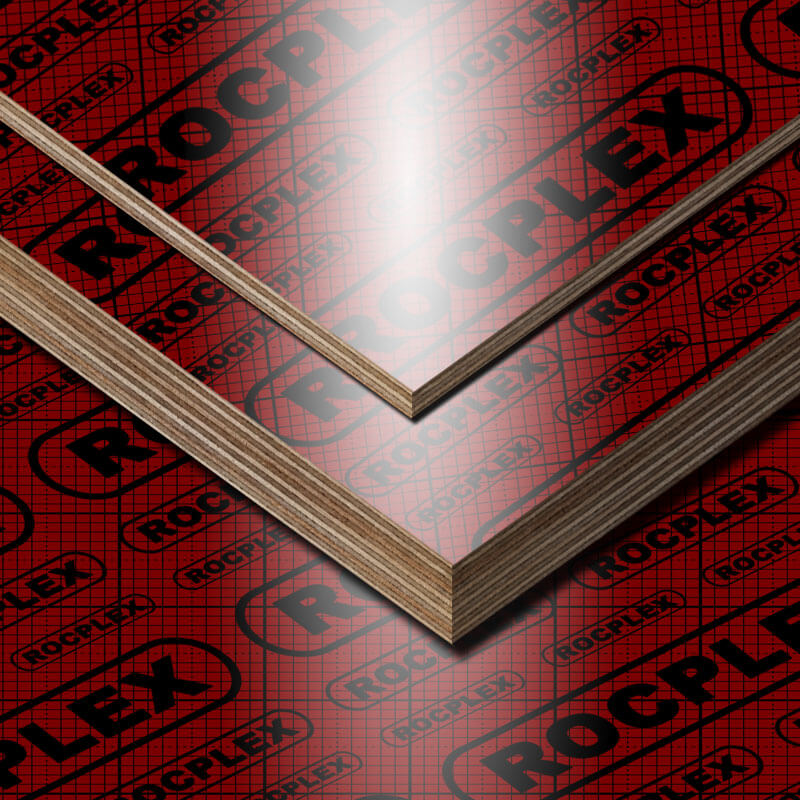

Meanwhile we also can supply you the formwork systerm accessories, commercial plywood , film faced plywood etc.

We specially professional in supplying antislip plywood.

Please contact our sales team for more detailed information regarding chinese film faced plywood.

Product detail pictures:

Related Product Guide:

China’s plywood production and import and export analysis in 2020: production is mainly wood plywood

Questions and answers encountered in the use of plywood plates

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for Manufacturer of Teak Timber - Film Faced Plywood – ROC , The product will supply to all over the world, such as: Zambia, Russia, America, We always insist on the management tenet of "Quality is first, Technology is basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.