What is Concrete wood forms?

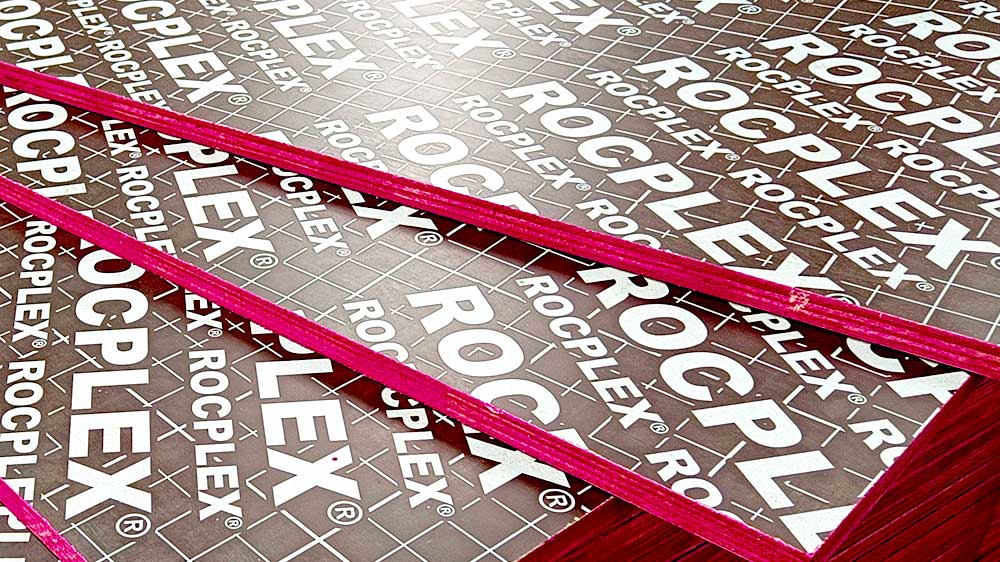

Concrete wood forms, commonly known as concrete form boards, shuttering ply, or shuttering plywood, are essential in modern construction. These forms are used to mold and set concrete, playing a crucial role in shaping structures from simple walls to complex architectural elements. Their versatility and strength make them a preferred choice for various construction projects, allowing for precision and durability in building work.

What Wood is Used for Concrete Forms?

Understanding the Material Choice

In the world of construction, the choice of wood for concrete forms is pivotal. Typically, plywood is the go-to material, renowned for its strength, flexibility, and reusability. Among plywood types, shuttering plywood stands out for its robustness and ability to withstand the weight and pressure of wet concrete. It’s engineered for high endurance, making it a practical and economical choice for formwork.

Advantages of Plywood in Formwork

The use of plywood in concrete formwork offers multiple advantages:

- Durability: Plywood withstands wear and tear, offering a longer lifespan.

- Flexibility: Its ability to be shaped into various forms makes it ideal for complex designs.

- Cost-effective: Compared to other materials like steel, plywood is more affordable.

How Do You Make Wood Concrete Forms?

Step-by-Step Guide

Creating wood concrete forms involves a straightforward process:

- Designing the Form: This initial step requires precise measurements and an understanding of the structure’s design.

- Cutting and Assembling: Plywood sheets are cut to size and assembled using screws and nails.

- Reinforcement: To enhance strength, additional supports are added.

- Finishing Touches: The form is treated with a release agent to ensure easy removal after the concrete sets.

Tips for Effective Formwork

For effective formwork, consider these tips:

- Accuracy in Measurements: Precision is key in formwork for structural integrity.

- Quality Materials: Use high-grade plywood for better results.

- Regular Inspection: Ensuring the formwork is intact and stable is crucial during the pouring process.

Is Timber Formwork Better Than Steel Formwork?

Comparing Materials

Timber formwork, primarily comprising plywood, offers distinct advantages over steel formwork:

- Cost-effectiveness: Timber is more affordable than steel.

- Ease of Handling: Timber is lighter and easier to work with.

- Adaptability: Timber can be easily cut and shaped for custom designs.

However, steel formwork has its benefits, like greater durability and suitability for larger projects. The choice between timber and steel largely depends on the project’s scale and complexity.

Environmental Considerations

Timber formwork is often seen as a more sustainable option, being a renewable resource. However, responsible sourcing and treatment of the wood are crucial to minimize environmental impact.

Environmental Impact of Steel Formwork

In contrast, steel formwork, while reusable and durable, has a higher environmental footprint. The production process of steel is energy-intensive and emits a significant amount of greenhouse gases. However, its longevity and reusability can partially offset these environmental concerns over its lifecycle.

Innovations in Concrete Wood Forms

Technological Advancements

The field of concrete wood forms is witnessing innovative changes, enhancing efficiency and sustainability. New treatments and coatings for plywood increase its durability and resistance to moisture, extending its lifespan and reducing waste. Additionally, advancements in manufacturing have led to more precisely engineered forms, ensuring better concrete shapes and structures.

Sustainable Practices

Sustainability in concrete formwork is gaining traction. The use of eco-friendly adhesives and sealants in plywood production, along with the practice of sourcing wood from certified sustainable forests, are steps toward greener construction practices. These initiatives not only benefit the environment but also add to the market appeal of these products.

Cost Analysis: Timber vs. Steel Formwork

Initial Investment and Long-Term Savings

While timber formwork generally has a lower upfront cost than steel, it’s important to consider the long-term aspects. Timber forms, although less durable than steel, can be more cost-effective for smaller projects or those with unique design requirements. Steel formwork, on the other hand, offers better cost efficiency for large-scale constructions due to its reusability and minimal maintenance needs.

Project Specific Cost-Benefit Analysis

The decision between timber and steel formwork should be based on a thorough cost-benefit analysis specific to each project. Factors such as project size, complexity, duration, and frequency of formwork reuse play a crucial role in this assessment.

The Future of Concrete Wood Forms

Emerging Trends

The future of concrete wood forms is shaped by several emerging trends. Digital fabrication techniques, such as CNC cutting, are being increasingly used for creating precise and complex formwork designs. Moreover, the integration of smart technologies for monitoring the curing process of concrete is another area of advancement.

Anticipated Developments

Looking ahead, we can expect further innovations in materials and methods. Biodegradable and recycled materials might find more applications in formwork manufacturing. Additionally, advancements in modular and reusable formwork systems are anticipated, aiming to reduce waste and improve efficiency in construction.

Challenges and Solutions in Concrete Wood Formwork

Overcoming Common Obstacles

In the realm of concrete wood forms, challenges such as moisture damage, warping, and limited reusability are prevalent. Addressing these issues involves:

- Improved Treatments: Advances in protective coatings and treatments help combat moisture and extend the life of plywood forms.

- Innovative Designs: Developing forms that are more resilient and adaptable to different construction needs.

- Maintenance and Care: Regular maintenance and proper storage of forms are essential for prolonging their usability.

Custom Solutions for Complex Projects

For complex construction projects, customized formwork solutions are increasingly sought after. These tailor-made forms accommodate unique architectural designs and ensure precision in concrete structures, aligning with the growing demand for bespoke construction.

Environmental Sustainability and Regulation

Balancing Construction and Conservation

The construction industry’s impact on the environment is a growing concern. In response, regulations and standards focusing on sustainable practices in formwork production and use are being implemented. These regulations encourage the use of environmentally friendly materials and promote practices that reduce waste and carbon footprint.

Future Regulatory Trends

Future trends in regulation are likely to emphasize greater sustainability. This might include stricter guidelines on the sourcing of timber, recycling of materials, and reduction of hazardous chemicals in the production of concrete wood forms.

Collaborations and Partnerships in the Industry

Building Industry Alliances

Collaborations between manufacturers, contractors, and environmental organizations are pivotal in advancing the field of concrete wood forms. These partnerships lead to innovative solutions, sharing of best practices, and a unified approach towards sustainable construction.

The Role of Technology and Innovation

Technology plays a crucial role in these collaborations. From the development of new materials to the implementation of efficient manufacturing processes, technological innovation is at the heart of evolving industry practices.

Training and Education in Formwork Construction

Importance of Skilled Labor

The effectiveness of concrete wood forms heavily relies on the skill of the workers handling them. Thus, investing in training and education is vital for ensuring quality and safety in construction projects.

Programs and Certifications

Various training programs and certifications are available, focusing on the latest techniques and safety practices in formwork construction. These programs not only enhance the skill set of workers but also contribute to the overall quality and efficiency of construction projects.

Concrete Wood Forms: Innovating Building Techniques

Reflecting on the journey through the world of concrete wood forms, it’s evident that this sector is a blend of tradition and innovation. From the choice of materials to the techniques employed, every aspect of concrete formwork is evolving to meet the demands of modern construction. The future looks promising, with sustainability, efficiency, and technological advancements leading the way. As the industry adapts and grows, concrete wood forms continue to be a fundamental component in building the structures of tomorrow.

Post time: Mar-19-2024