What is Film-Faced Plywood?

Film-faced plywood is an engineered wood product designed for strength, durability, and water resistance. It features a high-density overlay (HDO) film on both surfaces. This film creates a smooth, protective barrier that shields the plywood core from moisture, chemicals, and physical wear. ROCPLEX film-faced plywood stands as a leading example of this advanced product, combining high-grade raw materials with cutting-edge manufacturing techniques.

At its core, film-faced plywood consists of multiple veneer layers. These veneers are bonded using waterproof phenolic resin, ensuring long-lasting adhesion even under wet and humid conditions. The film layer adds an extra defense, making it ideal for demanding construction sites.

Why Waterproofing Matters in Construction

Construction environments often expose materials to harsh weather, including rain, humidity, and concrete slurry. Without proper protection, standard plywood absorbs water, leading to swelling, warping, delamination, and reduced strength.

Waterproofing helps preserve the structural integrity of plywood throughout repeated uses. Film-faced plywood addresses this need directly. The waterproof film prevents water penetration, while the phenolic resin bonding and edge sealing techniques provide additional layers of moisture defense.

ROCPLEX film-faced plywood ensures stability even after multiple cycles of wetting and drying. Contractors and project managers rely on its consistent performance to reduce material waste and lower long-term costs.

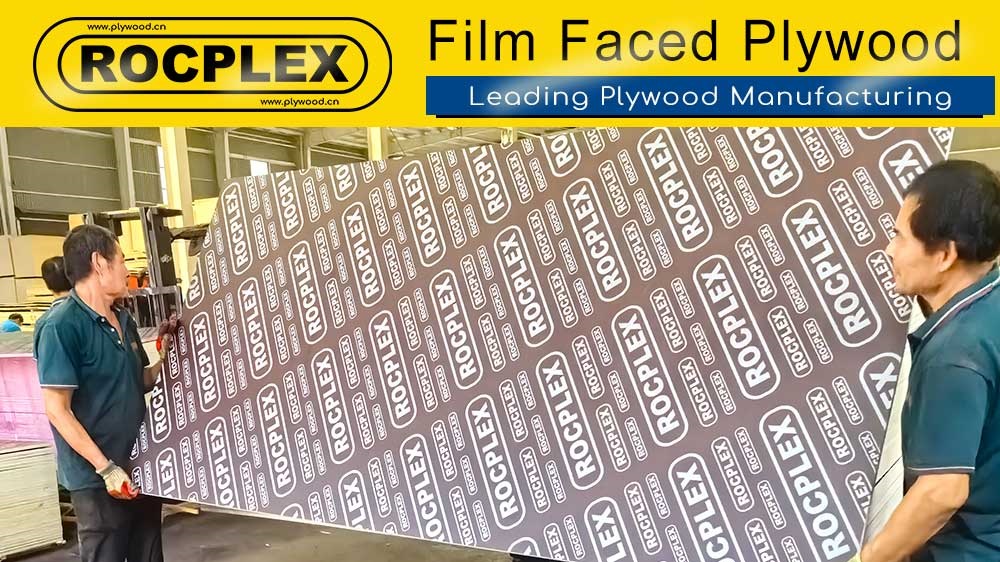

How ROCPLEX Produces Waterproof Film-Faced Plywood

ROCPLEX follows a meticulous production process to create its industry-leading film-faced plywood. The process begins by selecting premium-grade veneers. Each veneer undergoes careful inspection to eliminate defects such as knots, splits, or voids that may compromise strength and durability.

Next, the veneers are bonded using phenolic resin adhesive, which is specifically engineered for water resistance. The adhesive ensures that even under continuous moisture exposure, the bonds between veneer layers remain intact.

The hot-pressing stage follows, where high pressure and controlled heat fuse the veneers into a dense, solid panel. This process minimizes internal gaps and ensures uniform thickness across the sheet.

Finally, ROCPLEX applies a waterproof film to both faces of the plywood. This film layer resists scratches, abrasions, and chemical stains while significantly enhancing the board’s waterproof capabilities. To protect the panel’s edges—its most vulnerable areas—ROCPLEX applies waterproof edge sealing paint, forming a complete moisture barrier.

Is Film-Faced Plywood Completely Waterproof?

The term “waterproof” often causes confusion. While film-faced plywood offers exceptional water resistance, no wood product can be considered 100% waterproof under every condition indefinitely. Moisture can eventually penetrate if the edges are damaged, or if the panel remains submerged for prolonged periods.

However, for practical construction purposes, ROCPLEX film-faced plywood delivers excellent waterproof performance. Its film surface repels water, its phenolic resin prevents internal moisture absorption, and its edge sealing significantly reduces risks at vulnerable points.

When handled correctly, ROCPLEX panels withstand rain, humidity, and wet construction environments with ease, making them highly reliable for both temporary and repeated-use applications.

Common Uses of Waterproof Film-Faced Plywood

Film-faced plywood’s superior moisture resistance makes it a versatile material across various construction sectors. Common applications include:

Concrete formwork for slabs, columns, and beams.

Shuttering systems for bridges, tunnels, and dams.

Structural platforms and scaffolding.

Temporary outdoor enclosures and workstations.

Staging surfaces for events and exhibitions.

In each of these scenarios, ROCPLEX film-faced plywood offers reliable waterproof performance, reducing replacement frequency and maximizing cost efficiency.

Comparing Film Faced Plywood to Traditional Plywood

Traditional plywood lacks the waterproof film layer and uses adhesives that often fail under constant moisture exposure. When exposed to water, standard plywood absorbs moisture quickly, leading to swelling, loss of strength, and eventual breakdown.

Film-faced plywood eliminates these problems:

The film layer blocks water contact with the veneer surface.

Phenolic glue resists weakening under wet conditions.

Sealed edges prevent water from entering side grain areas.

ROCPLEX film-faced plywood maintains dimensional stability, even in challenging environments where traditional plywood would fail. Contractors appreciate its ability to endure rainstorms, concrete spills, and daily washdowns without compromising formwork accuracy.

How Long Does Film-Faced Plywood Last in Wet Conditions?

The durability of film-faced plywood depends heavily on quality, handling, and usage frequency. Under proper use and maintenance, ROCPLEX film-faced plywood delivers 10 to 20 reuse cycles or more.

Factors that contribute to its longevity include:

Premium veneer core selection.

Consistent phenolic bonding strength.

Durable film overlay resistant to wear.

Edge sealing protection against moisture infiltration.

Many ROCPLEX clients report higher-than-expected reuse rates, lowering material costs across multiple construction phases.

Maintenance Tips for Long-Term Waterproof Performance

Proper storage and handling are crucial for preserving the waterproof capabilities of film-faced plywood. Follow these maintenance guidelines to maximize service life:

Store plywood under cover to protect it from direct rain.

Stack sheets on raised platforms to avoid ground moisture contact.

Avoid dragging sheets across rough surfaces that may damage the film.

Inspect edges regularly for damage and reseal as necessary.

Clean off any concrete residue after each use to maintain the film’s protective surface.

By following these steps, contractors extend the plywood’s lifespan while maintaining its waterproof integrity throughout multiple projects.

Waterproof Film-Faced Plywood Across Global Construction Sites

ROCPLEX film-faced plywood serves contractors and wholesalers in diverse climates worldwide. From the humid tropical regions of Southeast Asia to the wet coastal markets of Europe, ROCPLEX panels maintain consistent waterproof performance.

Their resistance to moisture, temperature fluctuations, and chemical exposure makes them especially valuable for large-scale infrastructure projects where performance consistency is non-negotiable.

Waterproof Performance Under Extreme Weather Conditions

ROCPLEX film-faced plywood performs exceptionally well even under extreme weather conditions. Whether exposed to heavy rain, high humidity, or freezing temperatures, the panel maintains its waterproof performance.

Phenolic resin bonding remains stable even in sub-zero environments. The waterproof film layer resists expansion and contraction caused by temperature swings. Sealed edges protect internal veneers from moisture entry, even during prolonged exposure.

In regions where other plywood products fail, ROCPLEX remains stable, preventing costly delays and material losses. Contractors around the world trust ROCPLEX for consistent waterproof performance regardless of climate.

Chemical and UV Resistance

Film-faced plywood faces more than just water challenges on job sites. Concrete additives, cleaning agents, and prolonged UV exposure can deteriorate ordinary plywood rapidly.

ROCPLEX film-faced plywood resists these threats through:

High-density overlay film with strong chemical resistance.

UV-stable film surfaces that delay degradation under sunlight.

Phenolic resin bonds that tolerate chemical exposure without weakening.

These added protections allow ROCPLEX panels to maintain their waterproof integrity even when exposed to harsh job site chemicals and continuous sunlight.

Why ROCPLEX Film-Faced Plywood is the Trusted Choice

Not all film-faced plywood products offer the same waterproof reliability. ROCPLEX film-faced plywood stands out due to:

International quality certifications.

Uniform veneer thickness across all layers.

Superior glue bond strength through automated hot pressing.

Advanced film application technology for maximum surface protection.

Edge sealing with industrial waterproof coatings.

These advantages position ROCPLEX as a global leader trusted by contractors, wholesalers, and construction managers worldwide.

Is Film-Faced Plywood Waterproof for Long-Term Outdoor Exposure?

While film-faced plywood offers excellent waterproof resistance for construction work, it is not intended for permanent outdoor installations without protection.

For temporary outdoor exposure—such as formwork, scaffold platforms, or temporary structures—ROCPLEX film-faced plywood performs reliably. When projects require permanent exposure to rain and sun, marine plywood or specialized outdoor panels may offer better long-term waterproof durability.

In all short- to medium-term construction uses, ROCPLEX film-faced plywood remains one of the best waterproof plywood choices available.

Global Demand for Waterproof Film-Faced Plywood

The global demand for waterproof formwork solutions continues to grow. ROCPLEX serves major infrastructure, commercial, and residential projects across North America, Europe, the Middle East, Southeast Asia, and Oceania.

Wholesalers partner with ROCPLEX for:

Competitive factory-direct pricing.

Fast lead times and flexible production capacity.

Consistent batch quality across large-volume orders.

Professional technical support for end users.

As construction markets expand, demand for reliable waterproof film-faced plywood grows. ROCPLEX remains fully prepared to meet these global needs.

The Financial Benefits of Using Waterproof Film-Faced Plywood

While film-faced plywood carries a slightly higher upfront cost than standard plywood, its long-term savings make it far more economical:

Reduced sheet replacement due to high reuse rates.

Faster pour cycles through stable formwork dimensions.

Lower labor costs from easy cleaning and removal.

Higher-quality concrete surface finishes requiring less patching.

Contractors using ROCPLEX film-faced plywood report substantial cost savings after just a few reuse cycles, driving higher project profitability.

Frequently Asked Questions About Film-Faced Plywood Waterproofing

Q: Will the waterproof film peel off after several uses?

A: ROCPLEX applies its films with advanced hot-press bonding, minimizing peeling even after multiple reuses.

Q: Can I cut film-faced plywood without losing waterproofing?

A: Yes. However, always reseal cut edges using waterproof sealants to restore edge protection.

Q: Does temperature impact the waterproof bonding strength?

A: No. ROCPLEX phenolic resin remains stable across wide temperature ranges, protecting bond strength.

Q: Is film-faced plywood suitable for marine or dock applications?

A: For permanent water immersion, marine plywood may offer better long-term waterproofing than film-faced plywood.

Q: Can film-faced plywood resist heavy rainfall during construction?

A: Absolutely. ROCPLEX panels repel rainwater during active construction phases, reducing weather-related delays.

ROCPLEX Delivers Proven Waterproof Performance

Is film-faced plywood waterproof? Without question, ROCPLEX film-faced plywood delivers superior waterproof performance tailored to the needs of modern construction.

Through careful veneer selection, phenolic resin bonding, high-density overlay films, and precise edge sealing, ROCPLEX offers:

Excellent water resistance.

High reuse capability.

Dimensional stability in wet conditions.

Durable surface protection from wear, chemicals, and UV.

Whether you’re a contractor, wholesaler, or developer managing large-scale infrastructure projects, ROCPLEX film-faced plywood provides confidence, reliability, and real-world cost savings. Its proven waterproof performance makes it a cornerstone of global formwork systems across countless construction sites.

Post time: Jun-16-2025