What is film faced plywood?

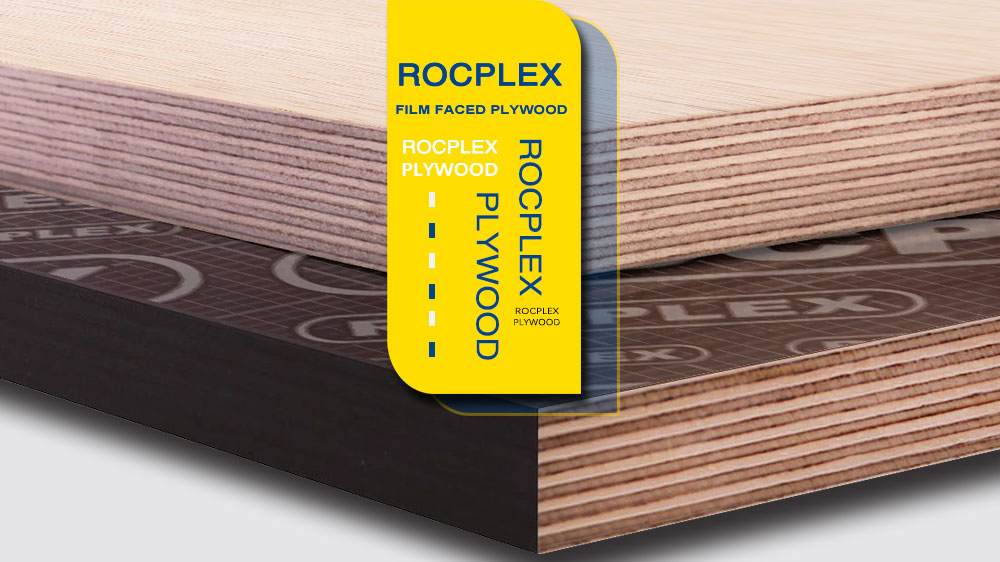

Film faced plywood is plywood with a phenolic resin film coating on its surface. This coating enhances durability, water resistance, and provides a smooth, clean finish. Construction professionals prefer this plywood type because it facilitates easy formwork removal after concrete setting.

Film faced plywood goes by several names, such as shuttering plywood or concrete form plywood. Its durability makes it essential for repetitive concrete pouring processes. Due to its waterproof plywood properties, builders use it in wet environments without risk of deterioration.

Understanding the Highest Face Grade for Plywood

The highest face grade for plywood represents the smoothest, blemish-free, and most durable plywood surface available. Selecting plywood with a superior face grade ensures fewer imperfections. Consequently, construction projects achieve superior surface finishes and structural integrity.

ROCPLEX film faced plywood achieves the highest face grade consistently. Its manufacturing process adheres to rigorous international standards, guaranteeing a flawless surface ideal for premium concrete finishes. Using high-quality plywood significantly reduces project costs by minimizing rework, waste, and labor hours.

Key Features of ROCPLEX Film Faced Plywood

ROCPLEX film faced plywood excels due to several remarkable qualities:

Waterproof plywood surface: The phenolic film coating guarantees maximum moisture resistance.

Superior durability: Resists abrasion and mechanical wear, perfect for repeated use in demanding construction scenarios.

Excellent surface smoothness: Provides a consistent and uniform concrete finish.

High strength-to-weight ratio: Offers ease of handling without sacrificing structural reliability.

These attributes underline why ROCPLEX film faced plywood stands out as a leading choice in global construction markets.

Why Construction Professionals Choose ROCPLEX

Professionals choose ROCPLEX film faced plywood due to its exceptional reliability. Construction sites globally demand plywood that withstands tough environments and repeated use without compromising quality. ROCPLEX meets these demands with ease, reducing operational downtime and costs.

Moreover, choosing ROCPLEX plywood ensures compliance with international quality standards. It assures construction teams of consistency, durability, and performance throughout extensive construction periods. Thus, ROCPLEX film faced plywood supports efficient project completion, making it highly recommended by global building material wholesalers.

Comparison: Film Faced Plywood vs. Shuttering Plywood

Film faced plywood and shuttering plywood terms often cause confusion. Both plywood types cater to concrete formwork. However, film faced plywood typically provides enhanced moisture resistance and surface durability.

ROCPLEX film faced plywood particularly emphasizes these attributes. Its advanced manufacturing methods ensure superior results compared to traditional shuttering plywood. Consequently, builders opting for ROCPLEX experience smoother finishes, increased reuse rates, and significant project savings.

How ROCPLEX Meets Global Standards

ROCPLEX’s dedication to quality control ensures compliance with global safety and durability standards. This meticulous approach involves rigorous inspections and tests at every production stage. Such thorough quality management guarantees the delivery of plywood that meets or surpasses industry expectations.

International construction firms trust ROCPLEX plywood for consistent quality assurance. Choosing ROCPLEX means confidently adhering to global project specifications, enhancing your project’s credibility and reliability.

Optimal Applications for ROCPLEX Film Faced Plywood

ROCPLEX film faced plywood suits various challenging applications, including:

Concrete slab formwork: Provides an ultra-smooth, seamless finish crucial for flooring and foundation works.

Vertical wall structures: Delivers excellent support and easy stripping, significantly saving time.

Bridge and tunnel construction: Withstands intense mechanical stresses, ensuring maximum safety and longevity.

Marine plywood applications: Ideal for moist and humid environments, resisting water damage and decay effectively.

Construction companies appreciate the versatility and adaptability of ROCPLEX plywood. Whether for heavy-duty construction projects or delicate architectural structures, it consistently delivers outstanding results.

Maintenance and Storage Guidelines

Proper maintenance extends the lifespan of ROCPLEX film faced plywood significantly. Following these simple guidelines maximizes performance and durability:

Clean the plywood surface immediately after formwork removal.

Avoid prolonged exposure to extreme weather conditions.

Store plywood flat in dry, ventilated areas away from direct sunlight.

Apply form release agents correctly to preserve the film’s integrity.

These basic care routines optimize your investment, ensuring each sheet maintains its highest face grade condition over extended periods.

Common Questions about Film Faced Plywood

Construction industry professionals frequently ask specific questions regarding film faced plywood. Here are concise answers to the most commonly searched queries:

How many times can film faced plywood be reused?

Quality film faced plywood like ROCPLEX typically allows for reuse between 15-30 times, depending on maintenance practices.

Is film faced plywood waterproof?

Yes, its phenolic film coating makes it highly resistant to moisture, qualifying it as waterproof plywood ideal for harsh environments.

What’s the difference between marine plywood and film faced plywood?

Marine plywood specifically resists marine conditions, whereas film faced plywood offers waterproof protection designed explicitly for formwork applications.

Can film faced plywood be painted?

Yes, although its smooth surface requires thorough cleaning and priming before painting.

Sustainable Manufacturing Practices

Environmental responsibility shapes ROCPLEX’s manufacturing philosophy. All plywood production methods strictly adhere to sustainability practices. The company sources timber responsibly, complying with international forestry standards. Additionally, the phenolic resin used in film faced plywood production minimizes environmental impact through lower emissions and recyclability.

Choosing ROCPLEX supports sustainable construction projects. Builders gain access to quality plywood products while aligning with green construction initiatives. Thus, investing in ROCPLEX film faced plywood contributes positively toward environmental preservation.

Customer Testimonials and Industry Reputation

Globally, construction experts praise ROCPLEX film faced plywood for superior performance and reliability. Numerous successful projects worldwide stand testament to its unmatched quality and versatility.

“ROCPLEX plywood significantly reduces waste, increasing our project’s efficiency,” says a prominent construction manager in Australia.

Wholesalers also emphasize ROCPLEX’s responsive customer support and consistent product quality. Reliable deliveries and exceptional product integrity make ROCPLEX plywood indispensable in construction markets globally.

Choosing the Highest Face Grade for Plywood: ROCPLEX Advantage

Selecting ROCPLEX film faced plywood guarantees the highest face grade available. Builders gain confidence from its reliability, cost-effectiveness, and exceptional durability. The ROCPLEX commitment to quality manufacturing provides unrivaled construction results, contributing positively to project outcomes.

Professionals who value premium finishes, ease of use, and sustainability consistently choose ROCPLEX film faced plywood. Elevate your construction projects by opting for the industry’s trusted standard in plywood excellence.

Post time: Jun-23-2025