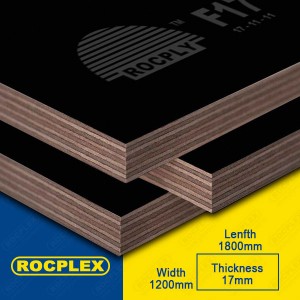

F17 Formply Competitive Price 1800X1200X17mm Australia Standard Plywood China F17 Formply for Construction Concrete

Being supported by an innovative and experienced IT team, we could present technical support on pre-sales & after-sales service for F17 Formply Competitive Price 1800X1200X17mm Australia Standard Plywood China F17 Formply for Construction Concrete, We never stop improving our technique and high quality to maintain up with the enhancement trend of this industry and fulfill your pleasure effectively. For anyone who is fascinated within our solutions, you should get in touch with us freely.

Being supported by an innovative and experienced IT team, we could present technical support on pre-sales & after-sales service for China F17 Formply, F17 formply, F17 formply price, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products and solutions in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

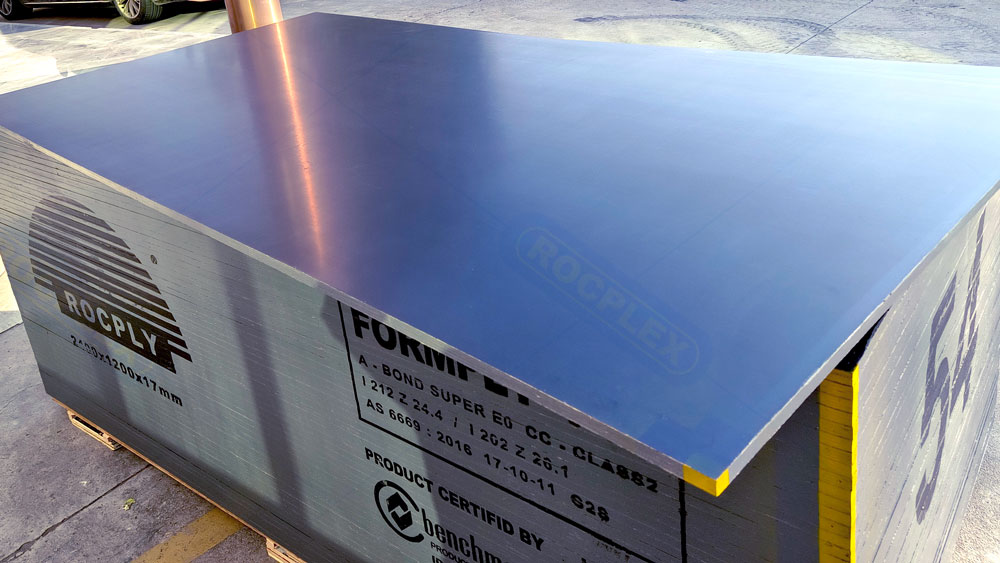

ROCPLY F17 Formply is plywood that is made from the high-density overlay (HDO) made of Phenolic resin-infused paper bonds to provide you with an incredible off-form finish. Its strength allows for multiple uses across all of Concrete, Building and Construction Industries.

ROCPLY F17 Formply for a strong concrete formwork that is stable, solid and stable.

Made from high-quality Full Hardwood Veneers joined together with Specially Designed Superior E0 Waterproof Adhesive. It has a superior bond strength.

Oblique Jionts and hot-melt splicing are employed to eliminate every gap.

ROCPLY Formply, a premium quality formwork plywood that has been developed especially for use in the Australian market.

A three-tier quality control program that includes

AA explicit Manufacturing Specification that is followed by the trained personnel;

Regular, thorough and documented in-house testing of the most important quality criteria and independent grading

Testing and certification is conducted with the help of Certemark Iternational (CMI) and DNV.

ROCPLY Formply assures high-quality and consistent.

The veneer that is used is certified by the Forest Stewardship Council (FSC) made from sustainable forests.

ROCPLY formwork plywood for solid, stable concrete formwork

ROCPLY FORMPLY was made at our plant in China for a period of more than 15 years. It is used with success throughout Asia, Australia and New Zealand.

ROCPLY FORMPLY is resistant to alkalines and dilute acids which increase the amount of use that can be made when combined together with concrete.

The surface of ROCPLY FORMPLY is extremely smooth, which reflects into the surface of the concrete.

ROCPLY FORMPLY is produced in China from plantation grown renewable core veneers of hardwood.

# If it is placed to boil for 72 hours it's still glue-sticking and not deformed.

Physical disposition is more favorable than moulds made of iron and meet the needs of building a moulds.

The iron alloys are very easy to deform and will not regain its smoothness after repair

If it is used, abide by the guidelines strictly, it may be used for more than 50 times.

• Reducing the price significantly and avoiding the negatives ( the rust and erosive effects of moulds made of iron)

# Solves the issues of rough and leaking during the building process.

It is particularly appropriate for projects with watering will give the surface of concrete a flat and smooth appearance.

# Having a greater economic gain.

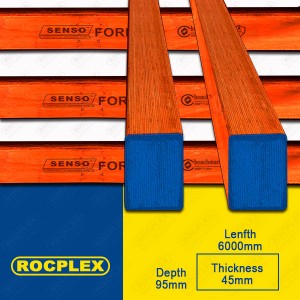

| Stress Grade | Sheet Size (mm) | Thicknesses (mm) | Weight (kg/sheet) | Parallel to face grain | Perpendicular to face grain | CoreMaterials | PackingUnit(sheets) | ||

| Momentof inertia | Sectionmodulus | Momentof inertia | Sectionmodulus | ||||||

| I(mm4/mm) | Z(mm3/mm) | I(mm4/mm) | Z(mm3/mm) | ||||||

| F17 SENSO | 1800×1200 | 12, 17, 19 & 25 | 24 | 240.0 | 27.6 | 178.0 | 22.9 | Full hardwood | 40 / 43 |

| F17 SNESO | 2400×1200 | 12, 17, 19 & 25 | 32 | 240.0 | 27.6 | 178.0 | 22.9 | Full hardwood | 40 / 43 |

ROCPLY Special Custom HDO Film Facing Does Not Absorb Water.

And It Does Not Swell Or Shrink.

The Robust, Smooth Surface Guarantees First-class Concrete Quality Even After Many Uses.

Manufactured From High-grade Full hardwood Veneers Bonded Together With Super E0 Waterproof Adhesive, Which Has Superior Bond Strength.

The Oblique Jiont And Hot-melt Splicing Technology Are Used To Avoid Every Possible Gap.

To Ensure Excellent Hardness And Stability.

Super E0 Waterproof Adhesive. If Put In Boiling Water For 72 Hours, It Is Still Glue-sticking And Non Deformed.

The Edges 4 Times Sealed With Waterproof Paint In The Factory For Minimise Moisture Penetration.

|

1 |

Face and Back |

ROCPLY Special Custom Film |

|

2 |

Grade |

AA garde |

|

3 |

Core Materials |

Full Hardwood Core |

|

4 |

Glue Choose |

A bond Waterproof Super E0 Glue |

|

5 |

Thickness |

6-28mm(normal thickness:12mm, 15mm, 17mm, 25mm) |

|

6 |

Specification |

1800mmX1200mm, 2400mmX1200mm 1800mmX600mm , 2400mmX600mm |

|

7 |

Moisture Content |

8-14% |

|

8 |

Density |

730-780 kg/ m3 |

| ROCPLY Fomply Save cost | ||

| Be special for phenolic glue and film | The formply can be disassembled and used repeatedly for both faces,saving 25% of the cost. | |

| Optimization for the special grade of core | ||

| Be special for adhesive | ||

| ROCPLY Fomply Shorten duration | ||

| Excellent effect of demoulding | Shorten 30% of the duration. | |

| Avoid the reconstruction of the wall | ||

| Be easy to incise and blend | ||

| ROCPLY Formply The high quality of casting | ||

| The flat and smooth faces | The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. | |

| The structure of waterproof and breathability | ||

| The edges are polished carefully | ||

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

10-12 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

20-27 pallets |

43 CBM |

25500KGS |

26000KGS |

Supported by an inventive and skilled staff We can provide technical support for pre-sales and after-sales support for F17 Formply Competitive Price 1800X1200X17mm Australia Standard Plywood China F17 Formply for Construction Concrete, We never ever stop enhancing our methods and quality to keep in line with the ever-changing trends in this field and provide your requirements efficiently. If you're interested with our solutions contact us today. contact with us immediately.

Fixed Competitive Price Fixed F17 Formply, China F17 Formply, F17 Formply Price. We are focused on providing support to our clients as a crucial aspect in building long-term relationships. We are always able to supply high quality products and solutions with our outstanding pre-sales service and after-sales support ensures competitiveness in an ever-growing global market.