ROCPLEX stage board, stage board,trailer floor mesh,trailer floor plywood

ROCPLEX stage board, stage board,trailer floor mesh,trailer floor plywood,

non slip film faced plywood,non slip plywood,semi trailer floor,stage board,trailer floor mesh,trailer floor plywood,

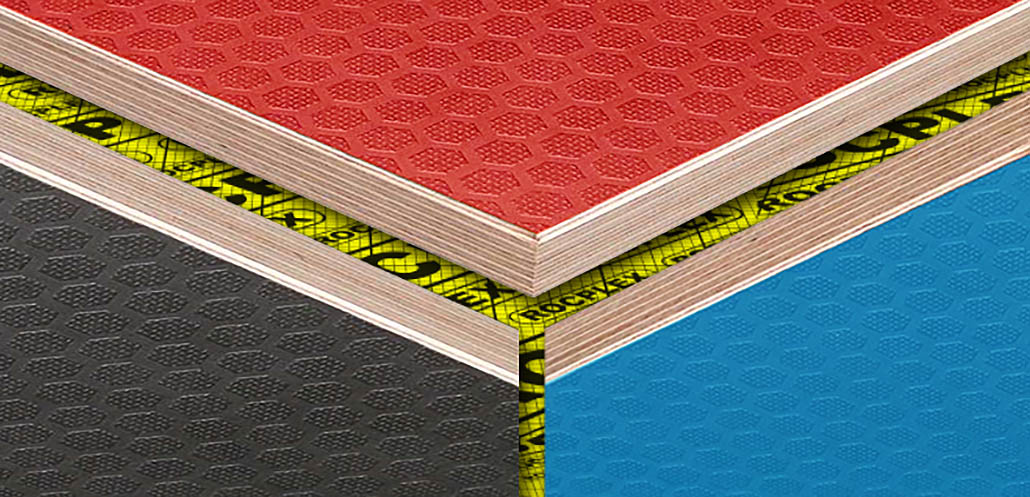

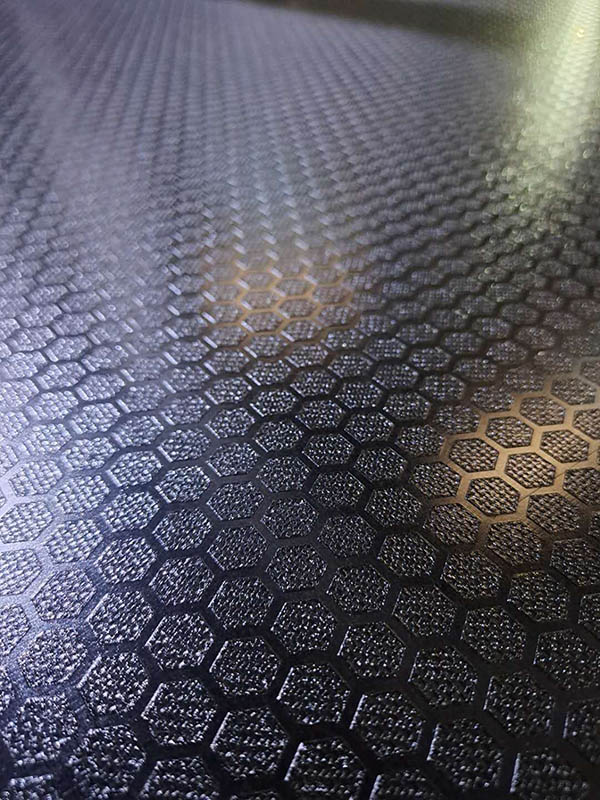

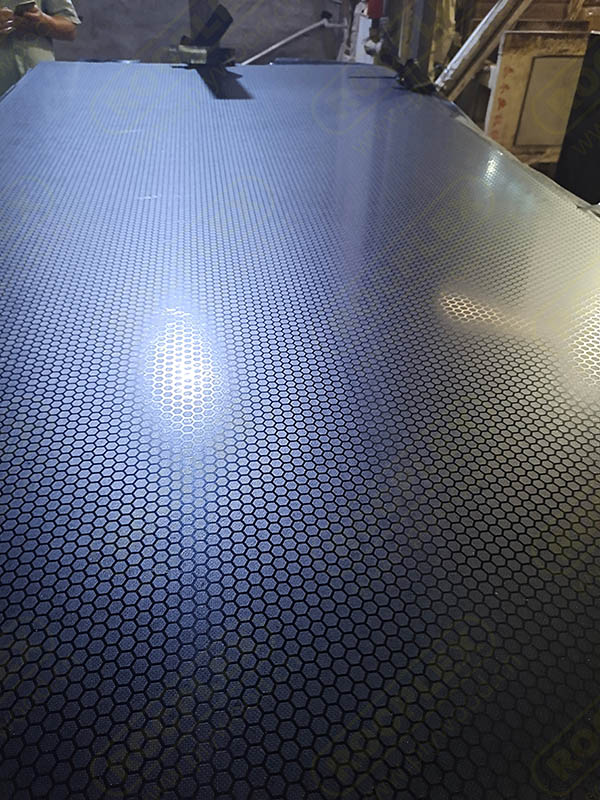

ROCPLEX antislip plywood is a strong 100% birch plywood coated with durable, slip-resistant and hard wearing waterproof phenolic film coating. During the coating process a slip resistant hexagonal pattern is hot pressed onto the film surface. The raised slip resistant hexagonal pattern maintains its anti-slip properties under a wide range of climatic conditions, and therefore ROCPLEX antislip plywood is an ideal material for demanding flooring.

The wear side has a rough antislip pattern and the reverse side is smooth film or raw plywood as needed.

The edges of anti-slip plywood are sealed 3 times with waterpoof paint. The wire mesh surface has high wear resistance and Anti-Slip properties.

ROCPLEX Floors are available in six thicknesses: 9 mm,12 mm,15 mm,18 mm,21mm,25mm. They are made of slip-resistant plywood and available in dark brown, light grey, black or red. Also an advanced option we offer plastic coated antslip floors, both are available in colour.

ROCPLEX Antislip Plywood Hexagon Antislip Plywood

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

7.5 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

690 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.68 Min: 0.81 |

Check out |

|

Damage Rate |

% |

85% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

6997 |

Check out |

|

Lateral |

6090 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

59 |

Check out |

|

|

Lateral |

43.77 |

Check out |

||||

|

6 |

Cycle Life |

About 15-25 Repeated Using Times Acoording To Projects By Formwork Application |

||||

■ 10 years experience produce antislip plywood for trailer floor.

■ Slip resistant surface, rating R12.

■ Very durable wear resistant surface.

■ Heat and cold resistant -30°C / +80°C.

■ Premium grade waterproof face and back.

■ High load bearing capacity.

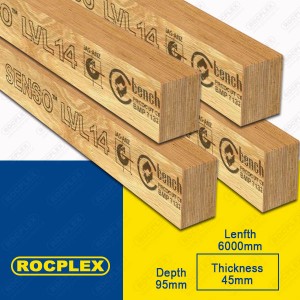

■ Sheet thicknesses: 3 to 40mm.

■ Good colour stability.

■ Available in kind colour surface appearance to choose.

■ Manufactured from sustainably-grown plantation hardwood.

■ Premium grade BC interior plywood panel.

■ Environmentally friendly product (contains no chlorine derivatives).

■ FSC certified upon request.

High load bearing capacity

Wear resistant surface

Slip resistant surface

Provide decorative slip resistant surface or wear resistant surface choice

Good colour stability (6-7 according to EN ISO 105-B02)

Environmentally friendly product (does not contain any chlorine derivatives)

Good colour stability

Easy to clean

Slip resistance surface

Decorative surface

Good crack resistance

Eco-friendly and renewable material

The surface maintains its original colour over the years even when exposed to changing weather conditions. The coating provides an easy to clean hygienic surface.

ROCPLEX antislip plywood is an ideal choice when floors require a very high-quality appearance. In addition to its decorative pattern and visual quality, the coating is UV and moisture resistant keeping its colour even in sunlight. The flooring panel is also easy to clean and resistant to most commonly used chemicals.

Strong and rigid birch plywood combined with a tough slip resistant coating make ROCPLEX antslip plywood an ideal flooring material for the various needs of transport and construction industries. The and durable coating protects the plywood against moisture penetration.

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

■ Vehicle floors

■ Terrace floors

■ Sports hall and playground facilites

■ Light transport trailers’ floors

■ Fittings for kitchens, offices, shops and exhibitions

■ Decorative surface

■ Scaffolding

■ Loading platforms

■ Stages, stands, terraces

■ Sports and playground facilities

■ Trailers floor

■ Aviation box manufacturing

■ Speaker manufacturing

Due to material availability and mill capability, ROCPLEX may be offered in slightly different specifications in particular regions. Please check with your local representative to confirm the product offering in your area.

Meanwhile we also can supply you the formwork systerm accessories, commercial plywood , film faced plywood etc.

We specially professional in supplying antislip plywood.

Please contact our sales team for more detailed information regarding chinese Antislip film faced plywood.

Along with the development of the industry stage, outdoor performance stage in the application of activity is becoming more and more people in addition to price the most attention on the stage, and beauty is becoming more and more demanding on the safety of the stage, the stage plate as stage one of the most part on the surface of the bearing, its robustness and practical performance, such as outdoor performances often encountered the weather changes, such as the rainy day, as a stage on the surface of the plate, the hard to avoid is caught in the rain or sole on wet, and in some cases, such as southern coastal areas, or air is humid, the stage of plywood moistureproof prevent slippery also appears especially important.

Along with the development of the industry stage, outdoor performance stage in the application of activity is becoming more and more people in addition to price the most attention on the stage, and beauty is becoming more and more demanding on the safety of the stage, the stage plate as stage one of the most part on the surface of the bearing, its robustness and practical performance, such as outdoor performances often encountered the weather changes, such as the rainy day, as a stage on the surface of the plate, the hard to avoid is caught in the rain or sole on wet, and in some cases, such as southern coastal areas, or air is humid, the stage of plywood moistureproof prevent slippery also appears especially important.

Standard requirements for stage plywood

The special stage anti-skate board is an important part in the construction of theater stage and gymnasium.

Outdoor flow has certain standards, norms and requirements for the production and installation of stage floor.

Density and strength of raw materials for plywood surface for special stage;

The cutting direction, the average moisture content and the expansion and contraction rate should be grasped during the processing and production period.

The resilience of the floor of the laying and installation process, the absorption rate of the actor’s jump and the requirements of the construction sound, etc.

Stage board surface requirements

What is the material of the stage board?

Does the quality of the stage board affect the stage price?

Stage boards are usually made of non-slip plywood.

For the same price of stage anti-skid plywood, our company generally adopts 18mm thick high-grade waterproof and anti-skateboard.

ROCPLEX non slip plywood stage board is a high-quality board made by hot pressing at high temperature, and its strength is 6-10 times that of ordinary wood board.

It has super waterproof, anti-skid, anti-corrosion, moth-proof and anti-aging characteristics, and it is not easy to deform when wet.

Selection of stage board surface material:

The wood used for the stage countertop of the opera house should be suitable for the requirements of performance function considering the mechanical properties of the wood, the specificity of the stage floor, and the resilience and vibration absorption of the stage floor. From timber volume density compared with the strength of wood, combined with domestic and international professional stage mesa material and myself many years of professional experience in the construction stage, generally choose the fir or Oregon pine (academic called North America yellow cedar, air dry density of 0.53 or so) as the surface of the floor plate stage, and the stage because the whole area is larger, number of splice plates very much, single block of the floor would have a big impact on the entire face after superposition. Accordingly, consider from the stability of lumber products, use first “point to be connected”, hind “break up”, the production technology that opens tonghou all round again, and point to be connected to but eliminate the defect such as scar of knot, crack, insect again, improve the comprehensive of qualitative material.

Commonly used stage plywood, twice formed, waterproof surface, standard 18mm thick, bearing 700KG.

Due to material availability and mill capability, ROCPLEX may be offered in slightly different specifications in particular regions. Please check with your local representative to confirm the product offering in your area.

Meanwhile we also can supply you the formwork systerm accessories, commercial plywood , film faced plywood etc.

We specially professional in supplying antislip plywood.

Please contact our sales team for more detailed information regarding china stage board.